As the maritime industry accelerates its transition to low- and zero-carbon fuels, engine developers face the urgent challenge of delivering clean, safe, and scalable propulsion solutions. In this exclusive interview, Sebastian Hensel, Vice President of R&D at WinGD, shares how the company is leading the charge with its ammonia-fuelled X-DF-A engine. From groundbreaking test results and safety innovations to the first commercial orders, Hensel offers deep insights into WinGD's role in shaping a greener future for global shipping.

1. What is the current development status of WinGD's ammonia dual-fuel engine? What key milestones have been achieved so far?

WinGD commenced its development work on ammonia fuel technology in 2019, and started its combustion development in 2021. This work has progressed since then through a sequence of carefully planned stages to reach the point where the first commercially available ammonia-fuelled engines will be delivered from 2025 onwards.

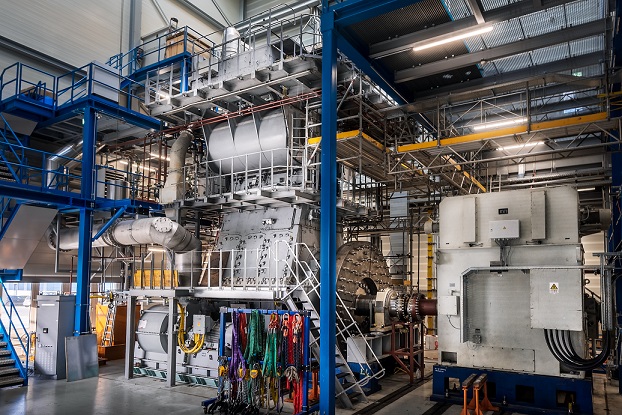

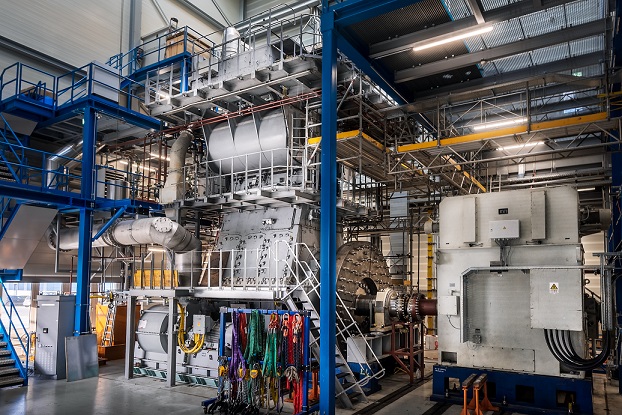

One of the main keys in this successful development project has been the use of proprietary technology, such as the unique, full-scale Spray Combustion Chamber that enables combustion phenomena to be observed under realistic two-stroke engine conditions. Another significant step was testing the technology on WinGD's unique single-cylinder engine, which allowed rapid validation of the ammonia combustion system under engine conditions. Performance and emission predictions based on the SCC and later rig testing, were subsequently confirmed via full-load engine testing. The full-load testing was carried out at the company’s Engine Research and Innovation Centre in Winterthur, Switzerland.

As WinGD's Vice President R&D, Sebastian Hensel, explains: "Our well-structured development approach has paid off. After intensive efforts to understand the principles of ammonia injection and combustion, we are the first two-stroke engine designer to demonstrate 100% ammonia operation with 5% pilot fuel consumption and such low emissions."

2. Could you share the latest emissions data from your ammonia engine testing? What are the key highlights? Do they meet IMO regulations?

Ammonia emissions from the WinGD X-DF-A ammonia-fuelled engine are below 10ppm, while nitrous oxide (N2O) emissions are below 3ppm. Nitrogen oxide (NOx) emissions for ammonia operation are well below those generated during diesel use. Crucially, the low emissions are achieved without the use of exhaust gas after-treatment, allowing WinGD to confirm that no ammonia slip catalyst (ASC) will be needed to operate the engine with ammonia fuel.

When combusted, ammonia fuel produces no CO2, sulphur, or particulate matter emissions, and is thus considered a prime alternative marine fuel candidate. However, optimal sustainability is achieved from so-called 'green' ammonia, which is produced using renewable energy sources, such as wind or solar power, rather than ammonia produced from natural gas or coal energy sources. Overall greenhouse gas emission reductions can only be reached with green ammonia fuel.

The WinGD X-DF-A engine is designed to be fully compliant with IMO regulations.

3. Emissions of byproducts like NOx and N₂O are major concerns with ammonia. What technical solutions has WinGD implemented to address these?

As indicated above, emissions of NOx and N2O from the WinGD X-DF-A engine are extremely low, and no ammonia slip catalyst is needed when operating the engine. Throughout the engine's development programme, proprietary technology was utilised to address and monitor emission levels. The full-load testing of the engine under real-life operating conditions has confirmed that NOx and N2O emission concerns have been successfully addressed.

The IMO NOx Technical Code (NTC 2008), which represents a means to certify the compliance of marine engines with NOx emission levels, was recently updated to include amendments related to the certification of engines subject to substantial modification or the use of multiple operational profiles. Clearly, this applies to dual-fuel engines.

However, as Sebastian Hensel points out: "NOx emissions are significantly lower when using ammonia fuel compared to diesel. As well as keeping the engine compliant with IMO's recently updated NOx Technical Code, this means we have a larger margin to use engine tunings to improve efficiency. As a result, our X-DF-A engine will have better fuel consumption than conventional diesel engines. This will be crucial to controlling operating costs, as renewably-produced ammonia is expected to be considerably more expensive than diesel."

4. Under what conditions were the recent tests conducted? Have real-world marine operating scenarios been considered or simulated?

The X-DF-A engine's development programme has been carefully structured with a step-by-step approach to ensure its capability to operate efficiently, safely, and sustainably. Early combustion tests and the validation of critical systems on dedicated test rigs, were followed by single-cylinder testing, and later by multi-cylinder engine testing representing real-world marine operation.. These tests validated the effectiveness of the full-scale engine, turbocharger configuration and control system when operating with ammonia fuel.

The company's full-scale Spray Combustion Chamber has enabled combustion parameters to be observed under realistic two-stroke engine conditions. Furthermore, multiple class approvals of the safety concept have been awarded. The importance of testing the engine under real-world operating conditions before the engine entered production has been central to the development protocol, and tests carried out with the engine operating under full-load have successfully replicated normal everyday operations.

5. How does the energy efficiency of the ammonia dual-fuel engine compare to conventional diesel or LNG dual-fuel engines?

WinGD's aim in all its development work is to deliver the best possible efficiency for all its engines. The efficiency of the X-DF-A dual-fuel engine is the same as that of the company's standard X-engines, regardless of whether it is being run on diesel or ammonia fuel.

Furthermore, there are no major differences in the engine load acceptance and dynamic behaviour between the X-DF-A engine and conventional diesel engines. In general, it can be stated that the same high-pressure injection concept applied to our X-Engines is well suited to operating with ammonia fuel, which means that the X-DF-A's engine efficiency is high at all times, regardless of the fuel being used.

6. Safety is a critical issue with ammonia as a fuel. How is WinGD addressing safety in the engine's design and operation?

Ammonia is toxic and corrosive, requiring careful handling and storage to ensure the safety of both the ship's crew and the marine environment. WinGD has addressed this issue, both in the design and development of the X-DF-A engine and in its training methodology. The company also takes an open and transparent approach to making it clear to owners and operators that modifications and additional engineering work are needed for ships to be capable of operating with ammonia-fuelled engines.

WinGD has developed its X-DF-A ammonia technology with a systematic approach that prioritises safety and a deep understanding of the fuel's combustion characteristics. The concept has been granted approvals in principle from several leading classification societies, giving ship operators the assurances they need to deploy them safely, with the first engines set to enter service in 2026. The company is now working closely with shipyards and early customers to translate safe design into safe installation and operation.

WinGD holds training courses to provide detailed information on all aspects of working with ammonia fuel. These courses include a strong focus on safety, as well as training on control system logic and mechanical components. Furthermore, the company is already actively assisting operators and maritime academies in preparing training syllabuses for the use of ammonia as a marine fuel, for example under a joint venture with AET and Akademi Laut Malaysia.

A risk assessment is also mandatory for ammonia engines (e.g. HAZID). WinGD has taken all the required design precautions and countermeasures, as recommended in class rules and based on IGC Code provisions, into consideration during the design of the X-DF-A engine. The requirements as regards engine room safety with ammonia engine installations are also a key feature of the company's training programme.

7. Which shipowners or yards are currently involved in your joint development programs? Are there confirmed ammonia-fueled newbuild projects using WinGD technology?

WinGD has secured some 30 orders to date for ammonia-fuelled X-DF-A engines, with sizes ranging from 52- to 72-bore, for a range of vessels including bulk carriers, gas carriers, container vessels and oil tankers. The first engines will be delivered from mid-2025 for ammonia carriers owned by Exmar LPG, and bulk carriers operated by CMB.Tech. The ships are to be built in Korea and China.

Joint development projects have played an essential role in bringing the ammonia-fuelled X-DF-A engines to the market. For example, WinGD, Swedish marine technology leader Alfa Laval, and the American Bureau of Shipping (ABS) are working with Korean shipbuilder K Shipbuilding (KSB) on the development of an ammonia-fuelled MR tanker design, under a memorandum of understanding signed in April 2024. The design will feature a 6X52DF‑A engine from WinGD.

WinGD and KSB are working to deliver fuel gas system specifications suitable for the vessel application and the selected engine, while Alfa Laval will deliver the detailed documentation for the final fuel gas system design. The design will be reviewed by ABS, with the aim of issuing an approval in principle.

As Sebastian Hensel explains: "We believe that partnerships are key to all future developments in our industry, especially when it comes to helping the industry reach its net-zero emission targets. Collaboration with like-minded partners have been a cornerstone of WinGD's ammonia engine developments, with several industry partnerships focused on vessel designs and crew training – supporting both the deployment of ammonia-fuelled engines and the preparedness of the maritime industry to operate them safely."

8. What are the main challenges to commercializing ammonia as marine fuel — such as fuel availability, supply chain readiness, and class society rules?

The main challenges to the widespread adoption of ammonia as a marine fuel are those related to storage and the bunkering infrastructure. Specialised equipment and facilities, which are currently limited in the shipping industry, are required for the safe and efficient handling of ammonia. Developing the necessary infrastructure to deliver ammonia from existing supply networks to vessels for bunkering will require significant investment and coordination.

As regards the fuel itself, the technical maturity and capacity to produce low-carbon (green and blue) ammonia remains low, although it is scaling up rapidly as demand emerges. The anticipated cost of green or blue ammonia is expected to be multiples of conventional marine fuel, although this is expected to reduce over the long-term as production matures, and as carbon pricing makes alternatives relatively more expensive.

Ammonia holds significant potential as a low-carbon fuel for maritime, offering a path towards cleaner, more sustainable operations. Whilst challenges remain, ongoing research and development efforts are paving the way for a future where ammonia plays a major role in decarbonising the maritime sector.

On the regulatory side, the International Maritime Organization (IMO) began the regulatory process for ammonia in 2021, and has since published interim guidelines for the safe use of ammonia as a marine fuel. These interim guidelines establish essential safety standards for ship design and operational practices, targeting key areas such as fuel containment systems, bunkering procedures, fire safety, and toxicity mitigation.

At the same time, classification societies are preparing, or have already prepared, class notations setting out certain requirements for ships operating on ammonia fuel.

9. In the context of the global green transition, how do you view the competition or complementarity between ammonia and other alternative fuels like methanol or hydrogen?

WinGD believes that different alternative fuels will have a role to play in the maritime sector's voyage towards net zero emissions. Ammonia, methanol, LNG and biofuels will all be utilised in some form or other, so we don’t see there being competition between which fuels to adopt. Rather, the choice will come down to which fuel is most appropriate for any individual vessel’s operating profile.

"The production of sustainable, renewable fuels of all types continues to advance, but long-term availability and cost remain uncertain. WinGD is committed to delivering reliable, efficient engine designs that enable decarbonisation across all candidate fuels," says Sebastian Hensel.

Currently LNG is a popular choice as an interim alternative fuel that bridges the gap between conventional diesel and future low- or zero-carbon fuels. Looking ahead, we see e-fuels – whether that is synthetic LNG or green ammonia and methanol - as being the most promising future-fuel candidates.

Ammonia has good energy density and does not need to be stored under compression or at very low temperatures. It is, however, toxic and highly corrosive, making it difficult to handle. Safety protocols are, therefore, essential.

Methanol is today made predominantly from natural gas, but the use of hydrogen from renewable-sourced electricity and recaptured carbon to make green methanol would make it carbon neutral. The real benefit of methanol is its ease of storage.

Biodiesel is another option. Fuels derived from biomass have great potential as a carbon-neutral energy source. They can be made in a variety of forms for use in both diesel and gas engines, either as a drop-in fuel or on its own. Perhaps the greatest obstacle to widespread adoption is the availability, or lack thereof, of the feedstock.

Hydrogen appears to have limited potential as a marine fuel, since its low volumetric energy density, meaning that the storage tanks need to be nearly twice the size of LNG tanks, plus its explosive and corrosive nature are major challenges. Its main role, therefore, will probably be as a building block for other fuels. Hydrogen-based fuels will offer greenhouse gas-free energy if they can be produced using electricity from renewable sources.

WinGD's range of single- and dual-fuel engines support maritime decarbonisation, whichever fuel pathway ship operators choose.

10. What are the next R&D focuses for WinGD in green fuels? Can we expect breakthroughs in other zero-carbon fuels in the near future?

At WinGD we are strongly committed to R&D, focusing on the development of leading, sustainable technologies for new generations of low-speed engines. Beyond the development of the X-DF-A ammonia fuelled engine portfolio, recently the company’s first methanol-fuelled engine successfully completed its sea trial. The ten-cylinder, 92‑bore X-DF–M engine is destined for a 16,000 TEU container ship and is the biggest methanol-fuelled engine built to date. "As interest in methanol and regulatory clarity increases, we anticipate the X-DF-M platform will become a key contributor to reducing greenhouse gas emissions from global shipping, commented Sebastian Hensel."

The addition of methanol capability to WinGD's engine line-up further extends the decarbonisation options available to deep-sea ship operators, which include the long-established X-DF LNG-fuelled engine platform and the ammonia-fuelled X-DF-A platform. There are 62 X-DF-M engines on order across bore sizes ranging from 52 to 92, in similar cylinder configurations and engine rating fields as diesel-fuelled X-Engines.

Methanol can be produced with low carbon emissions by using either biomass or renewable energy with captured carbon. The evolution of these fuel pathways – with similar routes towards green ammonia and e-diesel – will be essential for shipping’s energy transition, as will the engine technology to use emerging low- and zero-carbon fuels.

WinGD continues to develop innovative technologies to support the highest possible engine efficiency for its portfolio of diesel, LNG, ammonia and methanol-fuelled engines. An outstanding example of this approach is the company's Compression Ratio (VCR) technology. This technology is applicable to all WinGD dual-fuel X-DF engines, including its X-DF-A and X-DF-M versions. By eliminating any performance difference between dual-fuel and single-fuelled engines, VCR dramatically improves operational flexibility for ships powered by X-DF engines.

The overriding emphasis on WinGD's R&D strategy is to seek to achieve the best possible economic and environmental performance for its customers, regardless of the engine fuel selected. In this, we pay close attention to future emission regulations and requirements for both conventional and future alternative fuels.

by Xinde Marine News Zhang Han

Sebastian Hensel, Vice President of R&D at WinGD

1. What is the current development status of WinGD's ammonia dual-fuel engine? What key milestones have been achieved so far?

WinGD commenced its development work on ammonia fuel technology in 2019, and started its combustion development in 2021. This work has progressed since then through a sequence of carefully planned stages to reach the point where the first commercially available ammonia-fuelled engines will be delivered from 2025 onwards.

One of the main keys in this successful development project has been the use of proprietary technology, such as the unique, full-scale Spray Combustion Chamber that enables combustion phenomena to be observed under realistic two-stroke engine conditions. Another significant step was testing the technology on WinGD's unique single-cylinder engine, which allowed rapid validation of the ammonia combustion system under engine conditions. Performance and emission predictions based on the SCC and later rig testing, were subsequently confirmed via full-load engine testing. The full-load testing was carried out at the company’s Engine Research and Innovation Centre in Winterthur, Switzerland.

As WinGD's Vice President R&D, Sebastian Hensel, explains: "Our well-structured development approach has paid off. After intensive efforts to understand the principles of ammonia injection and combustion, we are the first two-stroke engine designer to demonstrate 100% ammonia operation with 5% pilot fuel consumption and such low emissions."

2. Could you share the latest emissions data from your ammonia engine testing? What are the key highlights? Do they meet IMO regulations?

Ammonia emissions from the WinGD X-DF-A ammonia-fuelled engine are below 10ppm, while nitrous oxide (N2O) emissions are below 3ppm. Nitrogen oxide (NOx) emissions for ammonia operation are well below those generated during diesel use. Crucially, the low emissions are achieved without the use of exhaust gas after-treatment, allowing WinGD to confirm that no ammonia slip catalyst (ASC) will be needed to operate the engine with ammonia fuel.

When combusted, ammonia fuel produces no CO2, sulphur, or particulate matter emissions, and is thus considered a prime alternative marine fuel candidate. However, optimal sustainability is achieved from so-called 'green' ammonia, which is produced using renewable energy sources, such as wind or solar power, rather than ammonia produced from natural gas or coal energy sources. Overall greenhouse gas emission reductions can only be reached with green ammonia fuel.

The WinGD X-DF-A engine is designed to be fully compliant with IMO regulations.

3. Emissions of byproducts like NOx and N₂O are major concerns with ammonia. What technical solutions has WinGD implemented to address these?

As indicated above, emissions of NOx and N2O from the WinGD X-DF-A engine are extremely low, and no ammonia slip catalyst is needed when operating the engine. Throughout the engine's development programme, proprietary technology was utilised to address and monitor emission levels. The full-load testing of the engine under real-life operating conditions has confirmed that NOx and N2O emission concerns have been successfully addressed.

The IMO NOx Technical Code (NTC 2008), which represents a means to certify the compliance of marine engines with NOx emission levels, was recently updated to include amendments related to the certification of engines subject to substantial modification or the use of multiple operational profiles. Clearly, this applies to dual-fuel engines.

However, as Sebastian Hensel points out: "NOx emissions are significantly lower when using ammonia fuel compared to diesel. As well as keeping the engine compliant with IMO's recently updated NOx Technical Code, this means we have a larger margin to use engine tunings to improve efficiency. As a result, our X-DF-A engine will have better fuel consumption than conventional diesel engines. This will be crucial to controlling operating costs, as renewably-produced ammonia is expected to be considerably more expensive than diesel."

4. Under what conditions were the recent tests conducted? Have real-world marine operating scenarios been considered or simulated?

The X-DF-A engine's development programme has been carefully structured with a step-by-step approach to ensure its capability to operate efficiently, safely, and sustainably. Early combustion tests and the validation of critical systems on dedicated test rigs, were followed by single-cylinder testing, and later by multi-cylinder engine testing representing real-world marine operation.. These tests validated the effectiveness of the full-scale engine, turbocharger configuration and control system when operating with ammonia fuel.

The company's full-scale Spray Combustion Chamber has enabled combustion parameters to be observed under realistic two-stroke engine conditions. Furthermore, multiple class approvals of the safety concept have been awarded. The importance of testing the engine under real-world operating conditions before the engine entered production has been central to the development protocol, and tests carried out with the engine operating under full-load have successfully replicated normal everyday operations.

5. How does the energy efficiency of the ammonia dual-fuel engine compare to conventional diesel or LNG dual-fuel engines?

WinGD's aim in all its development work is to deliver the best possible efficiency for all its engines. The efficiency of the X-DF-A dual-fuel engine is the same as that of the company's standard X-engines, regardless of whether it is being run on diesel or ammonia fuel.

Furthermore, there are no major differences in the engine load acceptance and dynamic behaviour between the X-DF-A engine and conventional diesel engines. In general, it can be stated that the same high-pressure injection concept applied to our X-Engines is well suited to operating with ammonia fuel, which means that the X-DF-A's engine efficiency is high at all times, regardless of the fuel being used.

6. Safety is a critical issue with ammonia as a fuel. How is WinGD addressing safety in the engine's design and operation?

Ammonia is toxic and corrosive, requiring careful handling and storage to ensure the safety of both the ship's crew and the marine environment. WinGD has addressed this issue, both in the design and development of the X-DF-A engine and in its training methodology. The company also takes an open and transparent approach to making it clear to owners and operators that modifications and additional engineering work are needed for ships to be capable of operating with ammonia-fuelled engines.

WinGD has developed its X-DF-A ammonia technology with a systematic approach that prioritises safety and a deep understanding of the fuel's combustion characteristics. The concept has been granted approvals in principle from several leading classification societies, giving ship operators the assurances they need to deploy them safely, with the first engines set to enter service in 2026. The company is now working closely with shipyards and early customers to translate safe design into safe installation and operation.

WinGD holds training courses to provide detailed information on all aspects of working with ammonia fuel. These courses include a strong focus on safety, as well as training on control system logic and mechanical components. Furthermore, the company is already actively assisting operators and maritime academies in preparing training syllabuses for the use of ammonia as a marine fuel, for example under a joint venture with AET and Akademi Laut Malaysia.

A risk assessment is also mandatory for ammonia engines (e.g. HAZID). WinGD has taken all the required design precautions and countermeasures, as recommended in class rules and based on IGC Code provisions, into consideration during the design of the X-DF-A engine. The requirements as regards engine room safety with ammonia engine installations are also a key feature of the company's training programme.

7. Which shipowners or yards are currently involved in your joint development programs? Are there confirmed ammonia-fueled newbuild projects using WinGD technology?

WinGD has secured some 30 orders to date for ammonia-fuelled X-DF-A engines, with sizes ranging from 52- to 72-bore, for a range of vessels including bulk carriers, gas carriers, container vessels and oil tankers. The first engines will be delivered from mid-2025 for ammonia carriers owned by Exmar LPG, and bulk carriers operated by CMB.Tech. The ships are to be built in Korea and China.

Joint development projects have played an essential role in bringing the ammonia-fuelled X-DF-A engines to the market. For example, WinGD, Swedish marine technology leader Alfa Laval, and the American Bureau of Shipping (ABS) are working with Korean shipbuilder K Shipbuilding (KSB) on the development of an ammonia-fuelled MR tanker design, under a memorandum of understanding signed in April 2024. The design will feature a 6X52DF‑A engine from WinGD.

WinGD and KSB are working to deliver fuel gas system specifications suitable for the vessel application and the selected engine, while Alfa Laval will deliver the detailed documentation for the final fuel gas system design. The design will be reviewed by ABS, with the aim of issuing an approval in principle.

As Sebastian Hensel explains: "We believe that partnerships are key to all future developments in our industry, especially when it comes to helping the industry reach its net-zero emission targets. Collaboration with like-minded partners have been a cornerstone of WinGD's ammonia engine developments, with several industry partnerships focused on vessel designs and crew training – supporting both the deployment of ammonia-fuelled engines and the preparedness of the maritime industry to operate them safely."

8. What are the main challenges to commercializing ammonia as marine fuel — such as fuel availability, supply chain readiness, and class society rules?

The main challenges to the widespread adoption of ammonia as a marine fuel are those related to storage and the bunkering infrastructure. Specialised equipment and facilities, which are currently limited in the shipping industry, are required for the safe and efficient handling of ammonia. Developing the necessary infrastructure to deliver ammonia from existing supply networks to vessels for bunkering will require significant investment and coordination.

As regards the fuel itself, the technical maturity and capacity to produce low-carbon (green and blue) ammonia remains low, although it is scaling up rapidly as demand emerges. The anticipated cost of green or blue ammonia is expected to be multiples of conventional marine fuel, although this is expected to reduce over the long-term as production matures, and as carbon pricing makes alternatives relatively more expensive.

Ammonia holds significant potential as a low-carbon fuel for maritime, offering a path towards cleaner, more sustainable operations. Whilst challenges remain, ongoing research and development efforts are paving the way for a future where ammonia plays a major role in decarbonising the maritime sector.

On the regulatory side, the International Maritime Organization (IMO) began the regulatory process for ammonia in 2021, and has since published interim guidelines for the safe use of ammonia as a marine fuel. These interim guidelines establish essential safety standards for ship design and operational practices, targeting key areas such as fuel containment systems, bunkering procedures, fire safety, and toxicity mitigation.

At the same time, classification societies are preparing, or have already prepared, class notations setting out certain requirements for ships operating on ammonia fuel.

9. In the context of the global green transition, how do you view the competition or complementarity between ammonia and other alternative fuels like methanol or hydrogen?

WinGD believes that different alternative fuels will have a role to play in the maritime sector's voyage towards net zero emissions. Ammonia, methanol, LNG and biofuels will all be utilised in some form or other, so we don’t see there being competition between which fuels to adopt. Rather, the choice will come down to which fuel is most appropriate for any individual vessel’s operating profile.

"The production of sustainable, renewable fuels of all types continues to advance, but long-term availability and cost remain uncertain. WinGD is committed to delivering reliable, efficient engine designs that enable decarbonisation across all candidate fuels," says Sebastian Hensel.

Currently LNG is a popular choice as an interim alternative fuel that bridges the gap between conventional diesel and future low- or zero-carbon fuels. Looking ahead, we see e-fuels – whether that is synthetic LNG or green ammonia and methanol - as being the most promising future-fuel candidates.

Ammonia has good energy density and does not need to be stored under compression or at very low temperatures. It is, however, toxic and highly corrosive, making it difficult to handle. Safety protocols are, therefore, essential.

Methanol is today made predominantly from natural gas, but the use of hydrogen from renewable-sourced electricity and recaptured carbon to make green methanol would make it carbon neutral. The real benefit of methanol is its ease of storage.

Biodiesel is another option. Fuels derived from biomass have great potential as a carbon-neutral energy source. They can be made in a variety of forms for use in both diesel and gas engines, either as a drop-in fuel or on its own. Perhaps the greatest obstacle to widespread adoption is the availability, or lack thereof, of the feedstock.

Hydrogen appears to have limited potential as a marine fuel, since its low volumetric energy density, meaning that the storage tanks need to be nearly twice the size of LNG tanks, plus its explosive and corrosive nature are major challenges. Its main role, therefore, will probably be as a building block for other fuels. Hydrogen-based fuels will offer greenhouse gas-free energy if they can be produced using electricity from renewable sources.

WinGD's range of single- and dual-fuel engines support maritime decarbonisation, whichever fuel pathway ship operators choose.

10. What are the next R&D focuses for WinGD in green fuels? Can we expect breakthroughs in other zero-carbon fuels in the near future?

At WinGD we are strongly committed to R&D, focusing on the development of leading, sustainable technologies for new generations of low-speed engines. Beyond the development of the X-DF-A ammonia fuelled engine portfolio, recently the company’s first methanol-fuelled engine successfully completed its sea trial. The ten-cylinder, 92‑bore X-DF–M engine is destined for a 16,000 TEU container ship and is the biggest methanol-fuelled engine built to date. "As interest in methanol and regulatory clarity increases, we anticipate the X-DF-M platform will become a key contributor to reducing greenhouse gas emissions from global shipping, commented Sebastian Hensel."

The addition of methanol capability to WinGD's engine line-up further extends the decarbonisation options available to deep-sea ship operators, which include the long-established X-DF LNG-fuelled engine platform and the ammonia-fuelled X-DF-A platform. There are 62 X-DF-M engines on order across bore sizes ranging from 52 to 92, in similar cylinder configurations and engine rating fields as diesel-fuelled X-Engines.

Methanol can be produced with low carbon emissions by using either biomass or renewable energy with captured carbon. The evolution of these fuel pathways – with similar routes towards green ammonia and e-diesel – will be essential for shipping’s energy transition, as will the engine technology to use emerging low- and zero-carbon fuels.

WinGD continues to develop innovative technologies to support the highest possible engine efficiency for its portfolio of diesel, LNG, ammonia and methanol-fuelled engines. An outstanding example of this approach is the company's Compression Ratio (VCR) technology. This technology is applicable to all WinGD dual-fuel X-DF engines, including its X-DF-A and X-DF-M versions. By eliminating any performance difference between dual-fuel and single-fuelled engines, VCR dramatically improves operational flexibility for ships powered by X-DF engines.

The overriding emphasis on WinGD's R&D strategy is to seek to achieve the best possible economic and environmental performance for its customers, regardless of the engine fuel selected. In this, we pay close attention to future emission regulations and requirements for both conventional and future alternative fuels.

by Xinde Marine News Zhang Han

The opinions expressed herein are the author's and not necessarily those of The Xinde Marine News.

Please Contact Us at:

media@xindemarine.com