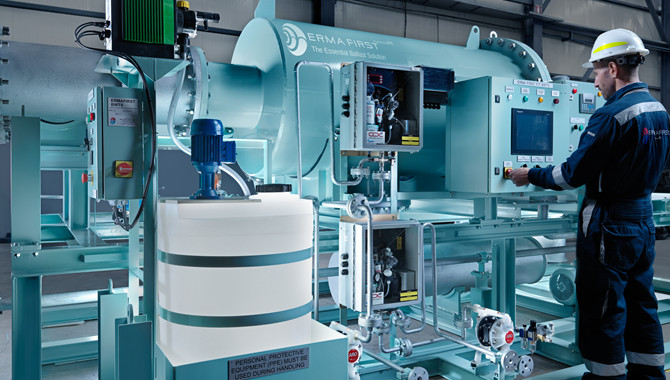

ERMA FIRST, an innovative Greek marine product manufacturer, has been developing ballast water treatment systems [BWTS] since 2009 As one of the most well respected BWTS specialists in world, they have successfully installed systems on a wide array of vessel types and sizes.

They currently hold an amended Type Approval from the China Classification Society (CCS) for its strong-selling FIT range of ballast water treatment systems and have been awarded Certificate under the Authority of the Government of the People’s Republic of China. The system, which uses advanced full-flow electro-chlorination technology, can be used on Chinese flagged vessels and is the first such system to receive approval in China under IMO Resolution MEPC 300 (72).

The approval is valid for the full range of models 75-3000 with the option of its three filter types: FILTERSAFE, FILTREX and HYDAC.

As a result, owners and managers of Chinese flagged ships have the option to install a highly flexible, simple to use, low energy and fully compliant ballast water treatment system.

ERMA FIRST has considerable experience working with Chinese shipyards on both newbuilds and retrofits, along with a proven track record across the international shipping industry as a whole. ERMA FIRST is proud to have a strong local technical presence through a Shanghai office and can provide excellent after-sales support both locally and globally.

The ERMA FIRST FIT ballast water treatment system has a small footprint and can be installed on coastal vessels as well as larger vessel types. Chinese waters vary significantly, ranging from clear offshore waters to highly turbid coastal areas. Using advanced full-flow electro-chlorination, backed up with a filtration system, means that ERMA FIRST FIT is able to cope with challenging waters without impacting cargo operations.

ERMA FIRST has 80 service engineers in China and has 10 years of experience installing and maintaining ballast water treatment systems. Its FIT system also holds USCG Type Approval, Final Approval by IMO and Class Type Approval.

Georgios Rentzeperis, ERMA FIRST Director in Shanghai, said:

"ERMA FIRST is ideally positioned to service the Chinese market with our expert engineers and considerable track record working in conjunction with regional shipyards, ship managers and owners. We offer a customer-centric and personal approach, which has served us well in both the Far East and Europe. Holding a Type Approval from the China Classification Society - and Certificate under the Authority of the Government of the People's Republic of China - is a huge honour for ERMA FIRST."

A superior solution

ERMA FIRST passionately believes a full-flow electro-chlorination proposition is the best all-round offering, both in terms of effectiveness and reducing OPEX.

The ERMA FIRST FIT BWTS comprises of a filter stage, followed by full flow electro-chlorination. Sea water is used in the disinfection stage to generate the requisite amount of disinfectant through the electrolysis of the filtered ballast water. The ERMA FIRST FIT BWTS system also employs special Electrodes that allow a broad environmental envelope of operation, while offering flexible solutions for both safe area and hazardous zone installation.

Water salinity and clarity can seriously affect the ability of a BWTS to work to its full potential. However, a full-flow electro-chlorination system - which is supported by filtration - can manage large volumes quickly with low power consumption. Turbidity and low ultraviolet transmissivity do not present the same challenges to an electro-chlorination system as they ordinarily would to a UV system.

The system is designed to deliver compliance for ships trading globally and has been uniquely tested and certified with three different 40µm basket filters. Each filter's performance has been proven in conjunction with the specially designed electro-chlorination cells. The achieved bio-efficacy meets and exceeds the dis-charge standards as defined by the International Maritime Organisation [IMO] and United States Coast Guard [USCG].

Focusing on OPEX

BWTS contributes to ship operational expenditure either directly or indirectly. BWTS power consumption is a direct OPEX. A stay in port due to BWTS flow restrictions in challenging water conditions would be regarded as an indirect cost.

Reduced UV intensity due to ageing UV lamps and quartz sleeves is an important example because it impacts UV dose, where flow reduction and/or power ramp up are resultant countermeasures. Operational modes designed to deal with specific operational challenges, in addition to system design limitations (SDL), provide a reasonable indication of factors that contribute to BWTS OPEX.

For more information on ERMA FIRST solutions please visit ermafirst.com

The opinions expressed herein are the author's and not necessarily those of The Xinde Marine News.

Please Contact Us at: