The industry should be optimistic that it can make the required future-proof investments needed to meet the IMO’s more ambitious targets, writes Scott Oh, Director, Asia Operations at Wärtsilä Exhaust Treatment

July 2023 was an important turning point for the maritime industry. The IMO moved from a target of 50% GHG reduction ambition by 2050, to net-zero by or around 2050. It set interim targets of 20%, striving for 30%, in 2030 and then 70%, striving for 80%, in 2040, compared to 2008 levels. These targets will be challenging, but there is cause for optimism, because, as well as having a positive business case today, scrubbers can now be installed ready for onboard carbon capture and storage (CCS).

Beyond sulphur cap compliance

The role of scrubbers in global sulphur cap compliance is well known. But, today, beyond solely tackling SOx, scrubbers have become a platform from which multiple technologies can work together in the stack and throughout the exhaust chain. This includes tackling NOx emissions by adding selective catalytic reduction systems (SCR) or exhaust gas recirculation systems (EGR) to ensure compliance with MARPOL Tier III requirements. In addition, scrubbers can reduce Particulate Matter (PM) 2.5 levels below even standard land-based requirements and a filter can be applied to capture microplastics. By adding the ability to be primed and ready for applying an onboard CCS system, they are a futureproofed investment for achieving marine decarbonisation goals in a short timeframe.

With the widespread between high and low sulphur fuels, scrubbers continue to present a favourable economic proposition, and payback time can be less than two years for several vessel types. Given the ongoing macroeconomic volatility and widening spread between prices of high and low sulphur fuels, the financial benefits are here to stay for the foreseeable future. Added to that, the cost of new, reduced density, low-carbon, alternative fuels, and the benefits of scrubbing are likely to continue for decades.

Asian recognition

Embracing this proven technology to bridge the gap between current and future environmental regulations will enable ship owners to move forward confidently with both newbuildings and retrofits. This has been particularly recognised in Asia and by Asian shipowners because it is here where Wärtsilä received its first order for CCS Ready scrubbers in November 2022. This order includes systems for four 8,200 teu container vessels which will be fitted with Wärtsilä’s CCS-Ready 35MW scrubber in an open loop configuration.

Building on this further, Wärtsilä and COSCO Shipping Heavy Industry signed a Memorandum of Understanding (MoU) covering the development of local production resources in 2019. This MoU ensures further development and support of Wärtsilä’s scrubbers in the region.

Wärtsilä is currently testing its CCS system at 70% CO2 capture rate at its facility in Norway, and a pilot installation will take place in early 2024. The CO2 capture part was ready at the beginning of 2022 and has undergone rigorous testing for more than a year. During that time, valuable experience has been gained on how to operate the system and pros and cons of the different types of solvents that can be used to capture the CO2.

The initial goal was to achieve control of the capture process. Now the liquefaction and storage modules have been installed, enabling end-to-end testing of the full CCS process, including storage, and offloading of the captured CO2.

The current focus of research is on finding the best, most advanced solvent technologies that have low or no toxicity, lower energy demand and improved carbon capture performance. Other characteristics that need to be considered are ease of handling, solvent availability, and, most importantly, the ability to integrate these solvents as a drop-in for existing systems and infrastructure.

Testing has resulted in enhancements to the original basic system design. Solvent development will continue until the full potential for further improvements is reached. This will continue before moving the process onboard a ship, which will be another major milestone in the process to get a commercially viable CCS product on the market by 2025.

As a mature technology with a strong return on investment, CCS Ready scrubbers can enable ship owners to futureproof their assets and meet the new compliance timetable with confidence.

Source:

Hong Kong Maritime Hub

The opinions expressed herein are the author's and not necessarily those of The Xinde Marine News.

Please Contact Us at:

media@xindemarine.com

Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar  Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar  Ningbo Containerized Freight Index Weekly Commentar

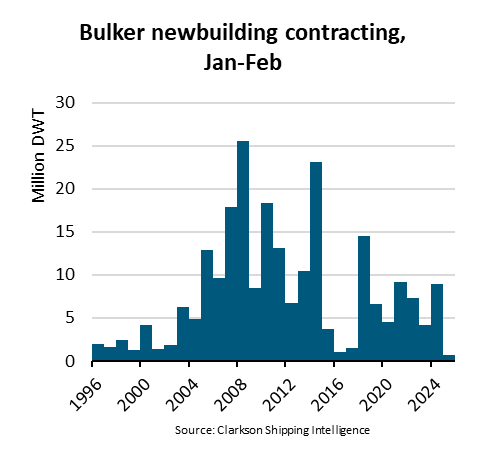

Ningbo Containerized Freight Index Weekly Commentar  BIMCO Shipping Number of the Week: Bulker newbuildi

BIMCO Shipping Number of the Week: Bulker newbuildi  Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar  Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar