There are less than 15 months to go until the one of the marine industry’s biggest regulatory changes. However, despite the proximity to the IMO’s 0.50 per cent sulphur cap in 2020, owners and operators continue to grapple with concerns about the practical management of their fuels, lubricants and engine operation. But while there are certain areas which remain out of operators’ control, there are others which they can and should be preparing for now.

The need for a management plan

As we edge towards the end of this year, and a critical preparatory time for the industry, it is finally getting what it’s been asking for - guidance. And lots of it.

The issue is, there is no one correct route to compliance; meaning this guidance differs depending on what you’re reading. But one message is consistent across writing on this subject: planning is crucial.

At ExxonMobil, we are working closely with operators to create a fuels and lubricants management plan for their operation. Every operation is unique and preparing early to ensure you are managing your inventories in order to achieve the most efficient switchover possible ahead of 2020 is essential.Your supplier will be able to help you find a fuels and lubricants solution that meets the needs of your business and delivers cost efficiencies over time that can enable your business to thrive.

Don’t forget your engine and cylinder oils

The changing emissions regulations are not only affecting fuel selection for most operators. The changes are also creating engine oil challenges. Selecting the right lubricants to cope with the changing fuel mix and evolving engine designs is a crucial step in maintaining efficient engine operations, minimising costly maintenance-related issues and optimising lubricant usage.

In fact, according to a recent report by marine mutual insurer, The Swedish Club, the single largest cause of main engine damage is

lubricant failure[1]. With failures, costing an average of $763,320. Based on this high cost, the report recommends that vessel operators implement robust on-board systems, including regular scrape down oil analysis, which has a proven track record of helping identify engine issues before they escalate.

Make the most of your onboard oil analysis

With operating conditions, changing so drastically, proactively staying informed of what is happening in an engine is fundamentally important. The speed at which engine issues can take hold requires an even faster response, which Mobil Serv℠ Cylinder Condition Monitoring can deliver.

At ExxonMobil, our recently launched Mobil Serv Cylinder Condition Monitoring service is taking scrape down oil analysis to the next level. By harnessing the latest in big data analysis, the service delivers actionable insights to operators within moments of testing. On-board engineers can rapidly react to the findings, taking steps to help reduce costly component damage and downtime, optimising lubricant usage in the process.Analysis of historic scrape-down oil data provides comprehensive insights into the performance of engines in a wide range of operating conditions, plotting trends and detecting issues before they cause trouble.

In addition, thanks to its XRF technology, the service is able to measure the sulphur content of the vessel’s fuel, compliant to industry standards. Ensuring you always get the most of your onboard analysis.

[1] The Swedish Club, “Main Engine Damage” Report, 2018,

https://www.swedishclub.com/media_upload/files/Loss%20Prevention/Main%20Engine%20Damage%202018/TSC-main-engine-web%202018%20%281%29.pdf

Sources:Iain White ,Director at Exxon Mobil Marine Ltd

Please Contact Us at:

admin@xindemarine.com

Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar  Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar  Ningbo Containerized Freight Index Weekly Commentar

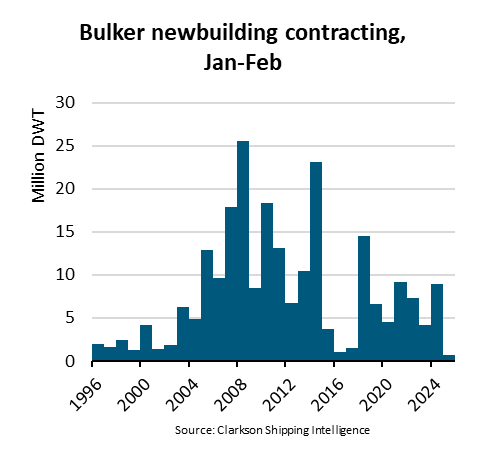

Ningbo Containerized Freight Index Weekly Commentar  BIMCO Shipping Number of the Week: Bulker newbuildi

BIMCO Shipping Number of the Week: Bulker newbuildi  Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar  Ningbo Containerized Freight Index Weekly Commentar

Ningbo Containerized Freight Index Weekly Commentar